Where do you go from here?

You’ve created a unique product, something you think the market will like and something you’re looking forward to releasing. Your plans are done, and you’re ready to go.

There’s just one thing missing: the manufacturer.

If it’s your first time trying to source a manufacturer, it can be an intimidating experience. That’s what this article is for—when you’re done, you’ll be completely prepared to find your own manufacturer.

Let’s dive in.

%(tableofcontents)

American Or Chinese?

Should you stick close to home or go overseas?

There’s no one-size-fits-all answer to this question. Both will have logistical challenges. In the case of American factories, so much of the manufacturing base has moved overseas that you may not be able to find a factory that can create your product, and not all product categories are covered. In addition, American factories can be more expensive than Chinese.

Why would you go local instead of overseas, then? There are a few reasons.

- Branding. Some audiences will respond better to an American-made product, which lets you incorporate that in your branding for a better appeal.

- Minimum order size. Depending on what your product is and what kind of demand you’re expecting, the order size may be a factor. You can often order a smaller amount of product from an American factory than one abroad, which may be important if you don’t want to keep a lot of inventory on hand.

- Easier verification. It can be hard to know what you’re working with if you’re dealing with an overseas factory. If you need help, platforms like Sourcify can help with vetting and verifying quality manufacturers.

- Faster shipping time. It takes time to get product to the port, across the ocean, to your port, through customs, and finally to your location. When it’s being made domestically it doesn’t take nearly as long.

So why go with Chinese and overseas factories over local?

- Cost effectiveness. The Chinese and overseas manufacturers are usually less expensive than American equivalents, due to differing labor and material costs.

- More variety. Many products aren’t even able to be made in the United States anymore because the factories don’t exist. You may have to go overseas.

- Volume. Foreign factories tend to be comfortable with large volumes of products, which can help streamline the process as well as help you get a large quantity to start.

There are some problems that you can encounter if you prefer to go overseas, however, especially in China (the most common overseas destination for manufacturing work.)

- Banned materials. You’ll need to be very aware of this, especially in the prototyping phase, There’s a long list of companies that have been burned by not paying attention to differing standards between the United States and China (one of the more recent examples is Lumber Liquidators who’s laminate flooring was made in China and failed to meet health and safety standards because it contained high levels of formaldehyde, a known cancer causing chemical).

- Tariffs. The United States recently implemented 25% tariffs on steel and 10% tariffs on aluminum from overseas (with certain exemptions), and this may play a role in how cost-effective overseas products can be. If in doubt, check the Harmonized Tariff Schedule to find out what you might wind up paying.[*]

A variety of factors will play into your decision, but once you’ve decided which direction to go, you can dig into the grunt work of actually finding the factory. Most of what we’ll cover here will deal with finding a quality factory in China.

Where Do I Start My Search?

It’s much easier to find a manufacturer now than it used to be.

When I started my eCommerce business, I was living in China and finding my products in the local markets. The products I was selling were sourced directly from the factory floor, which made it easier for me than it would be for someone overseas.

You probably aren’t going to be in the same sort of situation, so you’ll have to rely on the publicly-available tools to find a manufacturer. There are two general groups that these fall into:

Pre-screened platforms like Sourcify. This is the platform I built to pre-screen factories and make sure they’re up to standard. My goal was to eliminate the hassle, frustration and language barrier that comes with finding a trusted Chinese manufacturer. There is a flat fee for the service starting from $799, but our clients have found that the time and money saved has outweighed the cost.

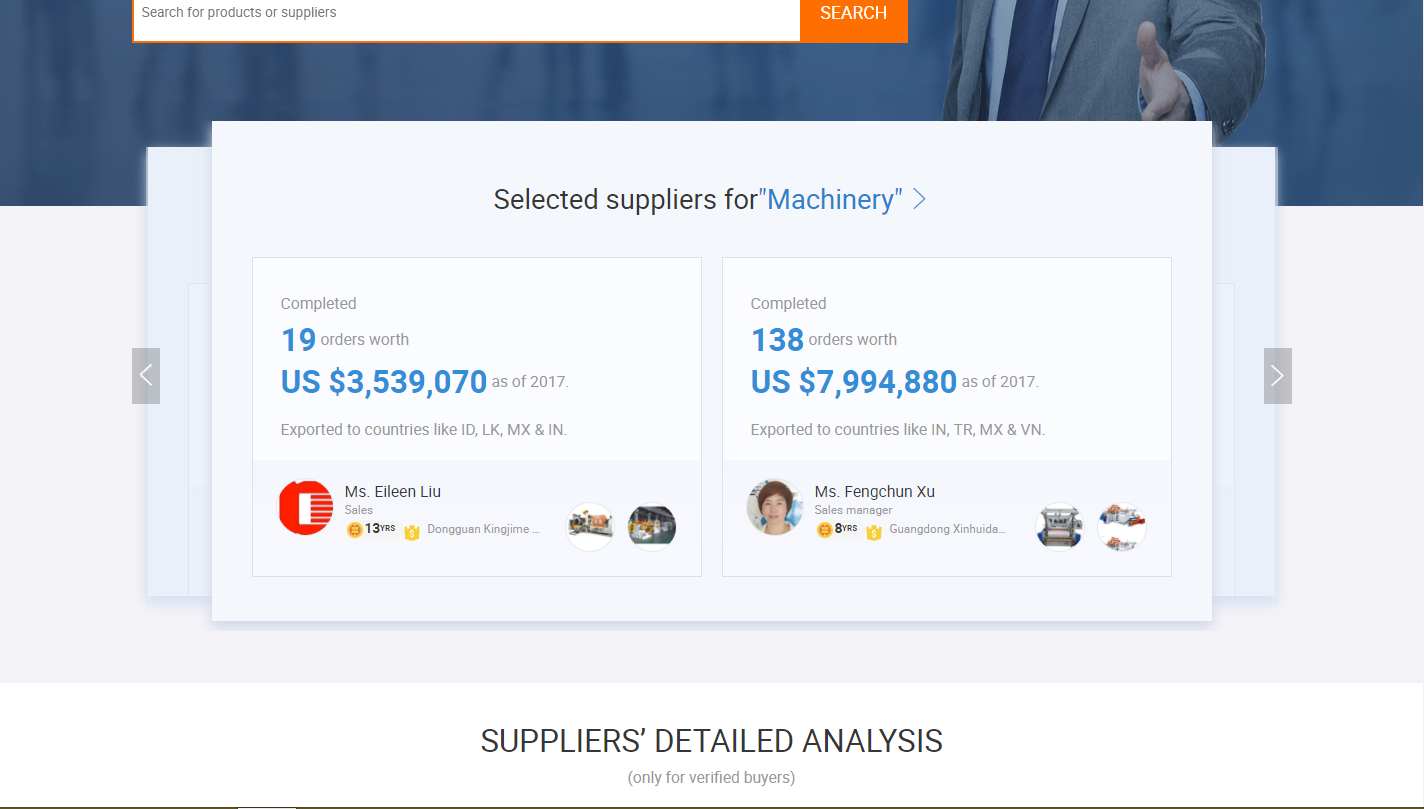

Open marketplaces like Alibaba and Global Sources. These are massive marketplaces, and there are just as many trading companies and wholesalers on it as there are actual manufacturers. Alibaba is huge, and they have a huge variety of producers, trading companies, and wholesalers rubbing elbows—with no easy way to tell which is which.

For example, can you tell from this Alibaba listing if these are suppliers, manufacturers or trading companies?

You can’t always tell on Alibaba.

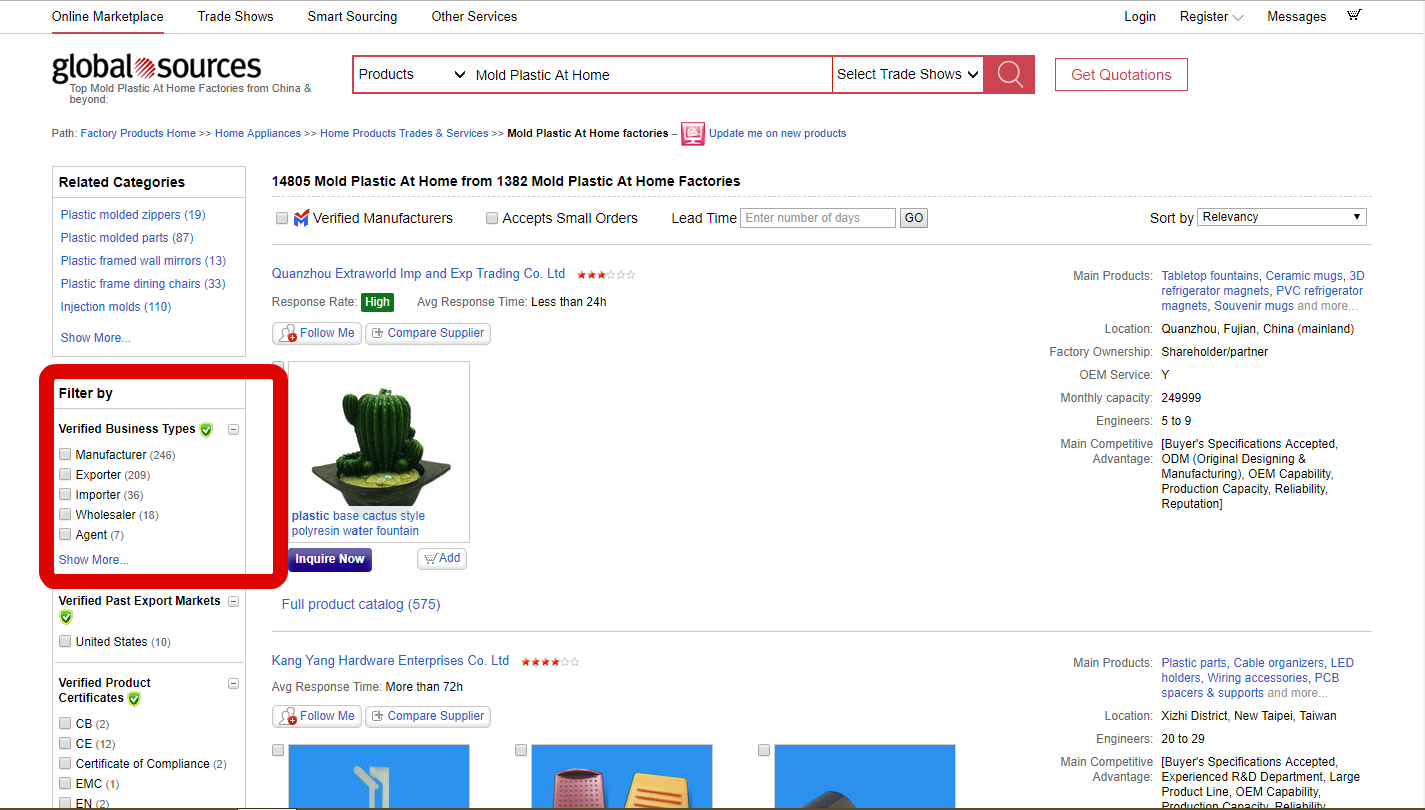

Global Sources is another traditional marketplace similar to Alibaba that’s commonly used for overseas sourcing. When you start looking, there’s a dizzying array of product categories, and as you start trying to narrow down it can be a little intimidating.

One way you can start to narrow your search is by filtering by “Verified Business Types” (pictured below).

If you want to make sure you’re buying from a factory and not a middleman, there are a few steps you can take. You can ask to see their business license, which should give you the information you need to verify they are who they say they are. Or you can use their location and business name to find their listing on China’s State Administration for Market Regulation website.[*]

Another thing to be aware of is checking to see a company has an email address registered to their own domain, not to a free webmail provider. It’s much harder to know who you’re dealing with if they don’t actually have a website of their own. It only takes five minutes to set up a free email address, but you could deal with the fallout of picking a company that doesn’t actually manufacture anything for much longer.

What Should I Know Before Choosing A Manufacturer?

When you’re choosing a manufacturer, you’re choosing a business partner.

Think about the attributes you want in a business partner: flexibility, reliability, trustworthiness… you probably have your own list. Those are a good starting point.

As far as manufacturer-specific needs, here are a couple of tips you should think about at the very beginning:

- Communicate clearly. Not everyone at overseas factories speaks English well. Some are using tools similar to Google Translate to read your emails. Avoid complex words that might get misunderstood, and keep your initial communications concise and to the point.

- Lists are your friend. Laying out your questions in a list format makes it easier to make sure every question is seen and answered, whether you’re dealing with English-speaking people or not.

- Use multiple platforms. Don’t just have one avenue of communication with a manufacturer. Make sure you have multiple ways to get in touch—email, phone, Skype, WeChat, or a variety of other methods.

- Have multiple contacts. What if your primary point of contact is away or leaves the company? Can you get in contact with someone else? Establishing a relationship with multiple people on the other end can go a long way. You should have a primary contact that you talk to, but knowing who to talk to if they’re away can save you both time and money.

- Check that the company has an export license. This isn’t often a problem, but it’s worth being aware of. Factories that don’t have export licenses can cause several problems:

-

They tend to be smaller.

-

They don’t have as many (if any) English speakers.

-

You’ll have to work your way through the complicated Chinese export bureaucracy instead of having it sorted out for you.

Most should have an export license—and if they don’t, it’s a clear sign of trouble down the line.

- Ask for references and a signed non-disclosure agreement (NDA). This is good for establishing a baseline and making sure you’re dealing with someone reputable, and while an NDA won’t necessarily stop copycats, it does give you some legal status.

- Know the local holidays and festivals. If you’re doing business with overseas manufacturers, you’ll need to know when national holidays and festivals fall. When will the factory be shut down, and when might your contacts be out of communication? Find out early, so you don’t get blindsided.

If you’re doing this up front, it can save you a lot of headaches down the line.

How Do I Get A Quote?

You’ve made it this far. Ideally, you’re in contact with several manufacturers, and you’re ready to send your plans or sample to the factory.

This is where the rubber meets the road. You want to make sure that you’re providing the maximum amount of useful information to the manufacturer, and that you’re getting a reasonable quote in return.

When you’re working with your plans or samples, there are some things to keep in mind. Be aware of American regulations that may apply to your product—a quick web search of each material that you’re planning to use can often make you aware of any major regulatory issues. California is usually the most restrictive American state as far as materials and environmental concerns, so if you’re trying to determine how compliant your product will be, start there.

California Department of Toxic Substance Control has put together a list of regulations your products should abide by in order to be safe for consumers.[*]

Make sure that you’re providing detailed information to your manufacturer as well. A sample is ideal, but the more details you’re able to provide the better. From dimensions to recommended materials, the more you can do up front, the less you’ll need to do in the prototyping stage.

Here are five questions to consider when you’re requesting a quote.

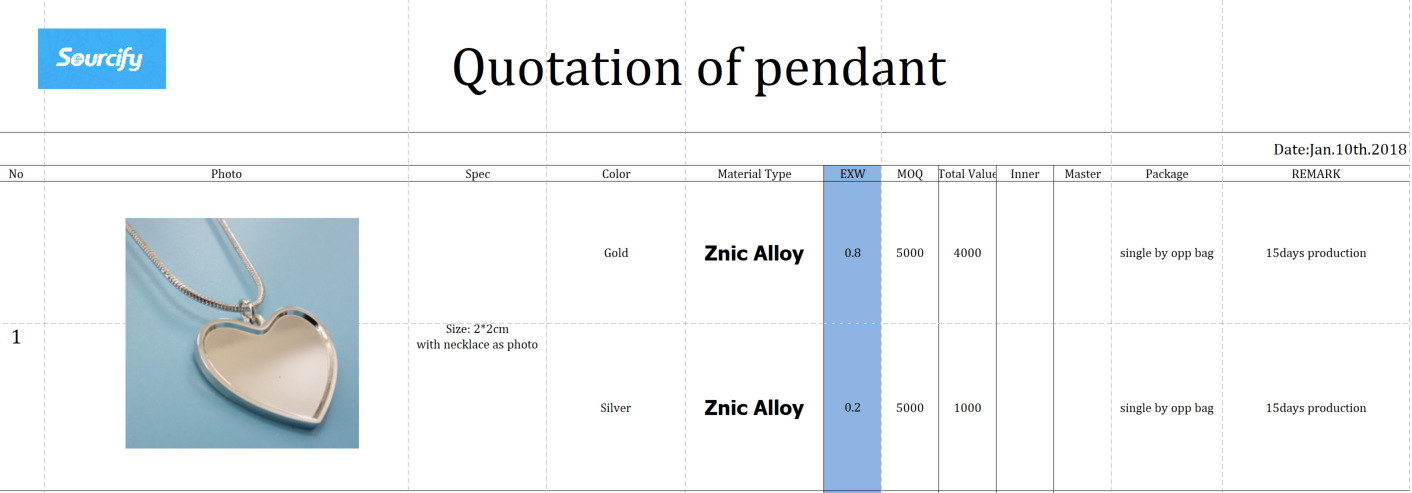

- What is your minimum order quantity? This is often abbreviated as MOQ. Make sure it’s manageable for you. Manageable doesn’t just mean in terms of the initial price, either: you’ll need to check how much storage space you have on hand, what you might spend in inventory taxes, and the other costs associated with carrying inventory.

- What is your sample pricing? You may have to pay a little up front to get samples. Depending on the manufacturer, it may range from an adjustment of the final product pricing to completely free.

- How much will my order cost? It might be good to ask for quotes for multiple quantities, as order volume may affect the price.

- How long will it take to fulfill my order? Knowing the turnaround time is essential. Timing can be very important, depending on your business. This isn’t just for the initial order, either—you’ll need to know for future orders, as well. Knowing your lead times will ensure you’re not out of product due to longer-than-expected manufacturing.

- What will my payment terms be? If you’re just starting out, you’re probably going to have to pay up front. Be aware of that going in. You can also ask for future payment terms—they may change as the factory gets more comfortable doing business with you. Are there any setup charges for each order? Sort everything out at the start.

Be concise and friendly, and provide all the information needed. You can use my request for quote template below to fill-in-the-blanks and get quotes for your product.

Get My Chinese Factory Request For Quote Template

When you receive a quote, there are also several things you need to keep in mind:

- Make sure you’re comparing apples to apples. Materials, processes, everything—if they’re different, you can wind up shooting yourself in the foot or not having a correct idea of pricing and quality. Go through it with a fine-toothed comb.

- Know your FOB (Free On Board) pricing if you’re dealing with an overseas factory. “Free On Board” refers to the point where ownership is transferred from the seller to the buyer—all costs before are assumed by the seller, and all after are taken care of by the buyer. FOB will be calculated to a specific port. That can make a big difference in what you need to do yourself. Dealing with shipping yourself can be rough, as you have to worry about every intermediate step in the transport chain.

- Negotiate! You know what sort of pricing you need to make a profit. Don’t be afraid to go back and forth with the factory a bit—they expect it. There are a variety of factors that play into this too, including payment terms. Will you have to pay up front? Can you pay over time at separate milestones? How much is the minimum order?

If the quote says something like “FOB Seattle”, you know you only have to deal with transportation from the port—although you should check to make sure all the customs fees and duties are paid for at the port. If it’s something like “FOB China”, you’ll have to deal with all the extra fees yourself.

You’ll need a customs agent and a freight forwarder to help in that case. They’ll be based out of China, and finding a good one can be hard (Sourcify is great for this). Know the basic terms for shipping charges too—there is a dizzying array of possible charges, but there are helpful guides that can tell you what you’re dealing with.[*]

And even when you get your goods, you can’t just drive up to the port and take ownership of your goods yourself. Know your local regulations, be aware of possible hazardous freight rules pertaining to your product, and you’ll be golden.

You should also familiarize yourself with the Basic Importing and Exporting section of the U.S. Customs website if you’re working with an overseas factory. This website will help you understand importing regulations, trade agreements and duty rates on the products you import.[*]

Once you’ve finished the quote process, you should have a pretty good idea of which manufacturer to choose. That’s when you go to the next step: prototyping.

How Do I Turn My Product Idea Into A Prototype?

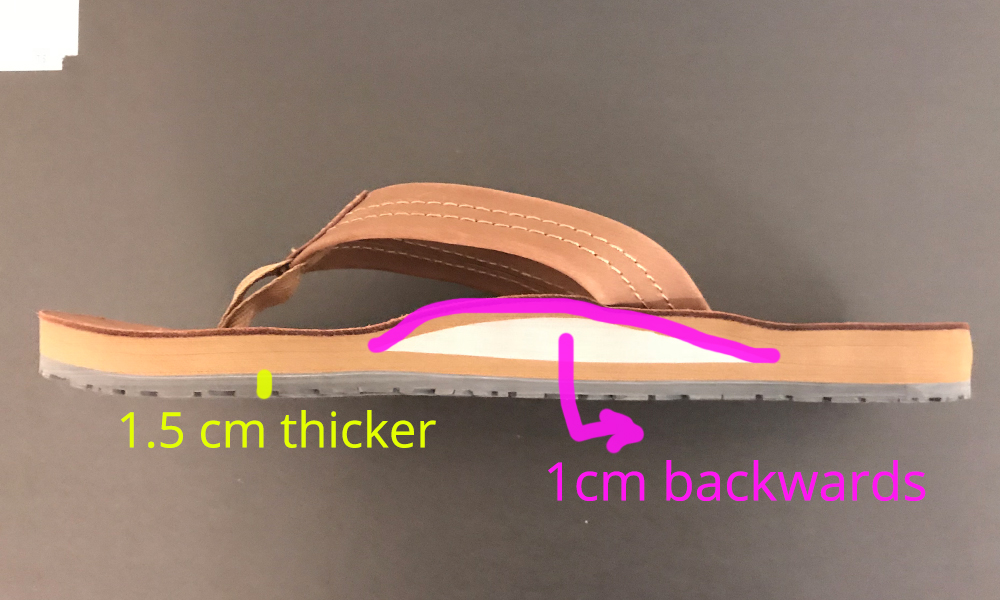

At this point, you’re receiving sample products from your manufacturer. Make sure you put the product through its paces to make sure it adheres to the standard that you laid out in your request for quote. Here are two critical things you should do:

- Take pictures and detailed notes, and send them back to the factory with your samples as you go.

- Work out the payment details.

This is the part where you get to iron out the kinks and make sure that your product is up to par. Make sure you’ve built some lead time into your production schedule here—sometimes it can take multiple months to get a product right, maybe even up to a year if there are significant issues to iron out. But it’s a lot easier to correct problems at this stage than it is once your line is in production (and a lot less expensive, too).

What will it cost for reworked parts if there’s something wrong with production? Who pays for shipping of bad parts back to the factory and good replacements from the factory? Sorting these out ahead of time will help you keep the relationship on a solid foundation and possibly save you money as well.

Once you’ve made sure that your product is ready to go, it’s time to enter production.

How Do I Turn My Prototype Into A Production Run?

After receiving a quality prototype that meets your requirements it’s time to begin a full production run. It’s recommended that you start with a smaller order at first as a trial to make sure the factory can deliver products that meet your standards.

-

Commit to a factory.

Choosing the factory that provided the best prototype is obviously the factory you would want to handle your production run, but what if multiple factories sent you high quality prototypes? Before committing to a factory make sure you’re comfortable with the level of communication, support, and assistance they provided during the prototyping stage.

Just because they provided an adequate prototype does not mean they’ll handle a full production run without issue. It’s best to work with the factory that truly understands you business needs.

-

Request a purchase order.

A purchase order is a legal document that outlines the requirements of the production run including: product types, quantities and the agreed upon price. Be as detailed as possible on your purchase order, if you accidently leave something out you may not have any legal recourse if your products aren’t manufactured exactly as you expected.

-

Be mindful of local holidays.

Holidays like Chinese New Year are widely celebrated in China and typically result in factories shutting down for at least 2 weeks, sometimes for over a month. It’s also not uncommon for production quality to decline shortly after the holidays as workers come back or new workers are brought on board. For time sensitive orders it’s best to plan far in advance to avoid production delays.

-

Make your initial payment.

Typically a factory will request a payment of 30% of the production price before they will begin your production run. After production is finished they’ll request the remaining 70% to complete your order. If your production run is small they may request 100% down before production begins, but always try to negotiate a smaller percentage to reduce your risk as your relationship with them hasn’t yet been established.

How Do I Get My Product Into My Hands?

Once your production run has started it can take months to get your product into your hands – typically it’s around 70 – 90 days from that first day of production to the day the products arrive at your place of business.

Whatever your product is, no matter how large or small, you’re going to need a place to store it—and you’ll need to have a way to get it from the port to your warehouse.

Once freight arrives at the port, it will need to be picked up and moved overland to its destination. Depending on how far your warehouse is situated from the port of arrival, either intermodal or over-the-road transport may be the best and most cost-effective transportation option.

Intermodal Transport

Intermodal transport uses multiple different methods to get the product to its destination without removing the freight from its container. Often, this means containers are picked up and transported by train to an inland transportation hub, where they’re transported to their destination by truck. Depending on quantity and distance, this can be the most cost-effective option.

Over-The-Road Transport

The other option is over-the-road truck transport, and if you’re dealing with smaller quantities you may see the term Less than Truckload (LTL) being used which means that your products take up less than a truck’s full capacity to ship. The size of your order will affect which one is best.

You also have to consider warehousing. If you’re dealing with small products (watches, ties, tools or other small consumer goods) and just starting out, it might be possible to work out of a garage, backyard shed or shop. For most, though, you’ll need to lease warehouse space so consider this leasing cost beforehand.

Now We Come To… The Beginning

You’ve decided whether to go domestic or overseas.

You’ve gone through the legwork of finding a manufacturer.

You know how to optimize your communications.

You’ve figured out the quote process.

And you know how to turn your product idea into a prototype, your prototype into a production run, and your production run into product at your door.

With these tips and tricks, you’re well-prepared to navigate the landscape of finding a manufacturer. Though it can be challenging, the end result is worth it, when you can see your product in the hands of your customers.

Add A Comment

VIEW THE COMMENTS